Welcome to the Office of the Associate Dean of Research and Graduate Studies

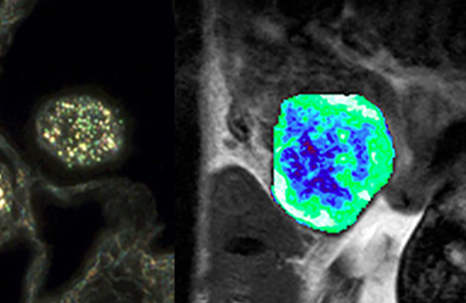

The Skaggs School of Pharmacy and Pharmaceutical Sciences has long been ranked a leader in NIH funding among schools of pharmacy and is routinely ranked as one of the most productive research units on the University of Colorado Anschutz Medical Campus. Here you will find information on the Office of the Associate Dean of Research and Graduate Studies, research centers and core facilities.

The Office of the Associate Dean of Research and Graduate Studies (ADRGS), led by Manisha Patel, PhD provides full-scope support for all research and sponsored projects coming into the Skaggs School of Pharmacy and Pharmaceutical Sciences. Dr. Patel is the chief research officer and oversees graduate programs in the Skaggs School of Pharmacy and Pharmaceutical Sciences appointed in her role in December 2022. She has been a faculty member at CU Anschutz since 2002. She has provided service and leadership on various institutional committees including serving as Vice-Chair for the School of Pharmacy’s Department of Pharmaceutical Sciences.

The Office of the Associate Dean of Research and Graduate Studies (ADRGS), led by Manisha Patel, PhD provides full-scope support for all research and sponsored projects coming into the Skaggs School of Pharmacy and Pharmaceutical Sciences. Dr. Patel is the chief research officer and oversees graduate programs in the Skaggs School of Pharmacy and Pharmaceutical Sciences appointed in her role in December 2022. She has been a faculty member at CU Anschutz since 2002. She has provided service and leadership on various institutional committees including serving as Vice-Chair for the School of Pharmacy’s Department of Pharmaceutical Sciences.

Dr. Patel received her Ph.D. in Pharmacology and Toxicology at Purdue University, and postdoctoral training in Neuroscience at Duke University. The primary theme of her laboratory's research is to understand the redox and metabolic basis of epilepsy and develop metabolism-based therapies for its treatment.

The office of the ADRGS provides full-scope support for all research and sponsored projects coming into the School of Pharmacy and Pharmaceutical Sciences. In addition, The ADRGS office administers several internal funding opportunities, such as the Skaggs Scholars program and internal ADRGS seed grants. We are proud to support over $18 Million in grant funding in the current fiscal year.

The office is also the home of all the Graduate Studies Programs within the School of Pharmacy. Together the Pharmaceutical Sciences PhD and Master's Programs, Toxicology, PhD program and Pharmaceutical Outcomes Research program has over 100 students enrolled. Our graduates are highly successful, well-trained scientists who work in many sectors including industry, pharmaceutical outcomes research, academia and state and federal governments.

The ADRGS organizes and sponsors the annual School of Pharmacy Research Retreat and hosts the Pharmacy Research in Progress seminars. For the Graduate Studies area, we bring in subject matter experts and hold many townhalls, lunch and learns, and other professional development seminars. In addition, the office support the Pharmacy Graduate Student symposium and other campus-wide student events.

Research Areas

Graduate Programs

In the News

World Renowned Researcher Tapped to Inspire Young Scientists

An international magazine focused on high school students contacts a renowned professor to interest kids in science. Sounds like the setup for a joke. But for Tom Anchordoquy, PhD, it's real life, and it allowed him to showcase his work and his team to a whole new audience — who may someday build on his research.

Lampe Team Garners $6.2 Million in Grants to Support Antibiotic and Drug Toxicity Research

Jed Lampe, PhD, and his team of researchers are focused on gaining a better understanding of the role of these minuscule yet potent molecules. Their goal is to harness their knowledge of how enzymes function to enhance the safety of medicines.

A Pharmaceutical Economist is Working to Lower Prescription Drug Costs in Colorado

Brett McQueen, PhD, is the team lead for an agreement with the Colorado Department of Health Care Policy & Financing (HCPF) to negotiate and track value-based contracts – agreements which help improve patient health outcomes and drive affordability by delivering savings to taxpayers.